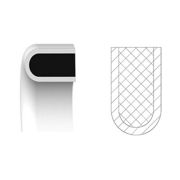

U Packing

U Packing is designed to be placed between the stem and bonnet of gate valves. This stem packing gives you a reliable seal for superior performance.

Its shell is made of virgin PTFE and the filler could be NBR, HNBR or FKM rubber Stem U packing is commonly used in oilfield valves. For a valve sealing system to be successful, the correct compound choice is also important for effective sealing and long-term service. Using superior materials and manufacturing processes. Its shell is made of virgin PTFE and the filler could be NBR, HNBR or FKM rubber Stem U packing is commonly used in oilfield valves. For a valve sealing system to be successful, the correct compound choice is also important for effective sealing and long-term service. Using superior materials and manufacturing processes.

Advantages:

- Suitable for low pressure application

- Excellent sealing performance

- Easy to install

- Cost-effective

Working Conditions

| Working Pressure | Working Temperature | Working Medium | Material |

| 0~15,000 PSI | PU | Hydraulic fluids, crude oil, sour oil/gas, H2S, salty water | PTFE+NBR/HNBR/FKM |

U Packing

U Packing is designed to be placed between the stem and bonnet of gate valves. This stem packing gives you a reliable seal for superior performance.

Its shell is made of virgin PTFE and the filler could be NBR, HNBR or FKM rubber Stem U packing is commonly used in oilfield valves. For a valve sealing system to be successful, the correct compound choice is also important for effective sealing and long-term service. Using superior materials and manufacturing processes. Its shell is made of virgin PTFE and the filler could be NBR, HNBR or FKM rubber Stem U packing is commonly used in oilfield valves. For a valve sealing system to be successful, the correct compound choice is also important for effective sealing and long-term service. Using superior materials and manufacturing processes.

Advantages:

- Suitable for low pressure application

- Excellent sealing performance

- Easy to install

- Cost-effective

Working Conditions

| Working Pressure | Working Temperature | Working Medium | Material |

| 0~15,000 PSI | PU | Hydraulic fluids, crude oil, sour oil/gas, H2S, salty water | PTFE+NBR/HNBR/FKM |