Valve Stem Packing

Valve Stem Packing

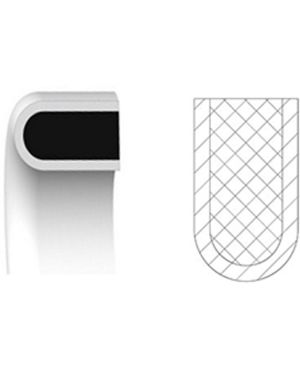

The valve stem packing is an essential component of valves, which is covered around the valve stem. The purpose of valve packing is to prevent leakage.

The tightness of the valve is one of the most important factors for the quality and performance of the valve. Especially for the imported valve, the requirements for the sealing performance of the valve are higher, requiring zero leakage when closed, including internal leakage and external leakage; The most important factor affecting the sealing performance is the valve sealing ring.

JST EST valve stem packing has good sealing performance under working pressure and a certain temperature range, and can automatically improve the sealing performance with the increase of pressure. This seal has passed the PR2 tests. They are built to meet the American Petroleum Institute’s high standards for design, materials, function and performance.

Advantages:

- The friction between the seal ring device and the moving part should be small, and the friction coefficient should be stable

- The sealing ring has strong anti-corrosion ability, is not easy to aging, has long working life and good wear resistance, and can be automatically compensated to a certain extent after wear

- The structure is simple, easy to use and maintain, so that the sealing ring has a longer life

| Working Pressure | Working Temperature | Working Medium | Material |

| 5,000~25,000 PSI | PU, LU, PX, LX | Hydraulic fluids, crude oil, sour oil/gas, H2S, salty water | PEEK+Elgiloy/SS steel+Filled PTFE |