Casing Head Packing Off Seals

Casing Head Packing Off Seals

In the drilling operation and oil and gas testing process, a casing head pack off seal, also called slip hanger, as a basic part of a wellhead assembly, is installed at the upper end of a casing string for suspending the casing string of each casing layer and sealing annular spaces between the casings of two adjacent casing layers. A slip seal is a main seal of the slip-type casing head, and performances there of directly affect the application range and normal use of the casing head.

Wellhead secondary pack off seals used to seal the hanger to the wellhead. The seal assembly may include a seal element and a lockdown member. The seal assembly is attachable to either one of the wellhead members by coupling the lockdown member to a locking surface on the wellhead member. The lockdown member and locking surface may include corresponding profiles for mating engagement thereby preventing relative movement between the wellhead member and seal assembly.

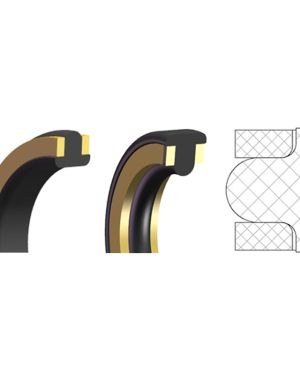

Pack off seal vary considerably in design. They generally comprise a square or rectangular section profile that is compressed axially in a housing to generate a radial sealing force against a casing or tubing. The packer may be homogeneous rubber, or incorporate reinforcement in the form of fabric, steel mesh.

Wellhead secondary pack off seals designed by JST can withstand the high pressure of 15,000 psi and the temperature range from –46°C to +121°C (–20°F to +250°F).

Working Conditions

| Pressure | Temperature range | Medium | Material |

| 0~15,000 PSI | LU, PU | Oil, water, Gas, H2S, CO2, etc. | NBR/HNBR/FKM+SS316 |